NC1800 Multi-functional Slipform Paver

Technical Specifications

NC1800 multi-functional slipform paver is a multi-purpose cement concrete construction equipment independently developed by our company. It is multi-purpose and can realize various mold configuration methods. It is widely used in road drainage ditches, drainage channels, curbs, shoulder stones, concrete guardrails, cement concrete structures, farmland water conservancy channels and other construction fields. It replaces the traditional process and significantly improves the construction quality and speed of cement concrete structures.

It features a large power reserve, full electronic control, full hydraulic power drive, proportional control, three-track traveling, automatic steering and leveling control system, and can complete the technological processes of vibrating, paving, and extrusion forming of cement concrete structures at one time.

1. Basic performance parameters

Maximum side paving height 1800mm

Maximum paving width 3000mm

Paving speed (0~10) m/min

Running speed (0~28) m/min

2. Power system

Engine model QSB3.9-C130-30 (Dongfeng Cummins)

Rated power/speed 97kW/2300r/min

Diesel tank capacity 360 L

3. Traveling system

Three tracks (two in front and one in rear), hydraulic independent drive, proportional control two-speed motor, planet-gear speed reducer with large rations, closed-loop control of paving speed, and PID adjustment

Track width 300mm

Track length 1600mm

Climbing capacity ≥25%

4. Outrigger steering lifting device

The three-track steering gear is equipped with displacement sensors for accurate proportional control and it can realize crab-type walking and cooperative steering, with a small turning radius; hydraulic proportional control of outrigger lifting

Minimum turning radius 4600mm

Hydraulic lifting stroke of outrigger 1120mm

Mechanical adjustment stroke of outrigger 500mm

5. Outrigger swing and slide device

The inner and outer swing of the right front outrigger, the expansion of the left front outrigger, and the expansion of the rear outrigger can be realized through hydraulic adjustment

Inner and outer swing amplitude of right front outrigger 680mm

Telescopic stroke of left front outrigger 1100mm

Telescopic stroke of rear outrigger 710mm

6. Hydraulic System

Imported load-sensitive multi-pump hydraulic system, proportional control traveling, outrigger steering lifting, and vibrating rod

Hydraulic oil cooling Large-size radiator and forced air cooling

Hydraulic oil filter Equipped with oil suction filter and oil return filter with a filtering accuracy of 10μm

Capacity of hydraulic oil tank 410L

7. Electrical control system

Humanized design of the console, man-machine interaction control panel, clear graphic identification mark, 24V-voltage power supply system

Equipped with two longitudinal slope sensors, one transverse slope sensor, and two steering sensors

Electronic automatic control is adopted for longitudinal slope, transverse slope, and steering sensors, and CAN bus is adopted for the communication between the sensors and controller.

Equipped with IoT platform, construction management and monitoring system, and alternative remote control device

8. Auger feeding device

The hydraulic motor drives the reducer, and the tilt and extension of the auger feeding device are adjusted through hydraulic pressure

Auger speed (0~70) r/min

Size of auger feeding device Length: 4400mm, blade diameter: 420mm

9. Vibratory compaction system

Imported hydraulic vibrator, with independently adjustable vibration frequency and proportional control

Vibrating rod interface 8 (10 is optional)

Vibrating rod frequency (0~200) Hz

10. High-pressure flushing device

Hydraulically driven high-pressure ceramic plunger pump, equipped with coiler and high-pressure flushing water gun

Water tank capacity 310L

11. Mold and mold fixing device

Various molds can be customized according to the needs of working conditions to meet the requirements of right-side paving and middle paving

Hydraulic horizontal stroke of mold fixing device 1000mm

Hydraulic vertical stroke of mold fixing device (double cylinders) 360mm

Mechanical vertical stroke of mold fixing device 240mm

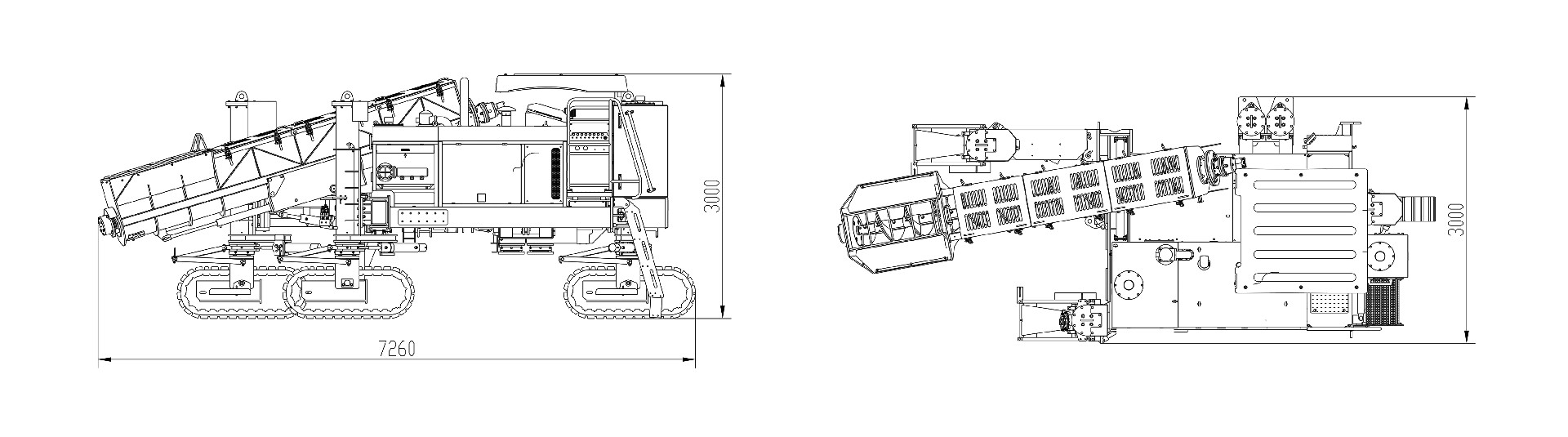

12. Overall dimensions and weight (transportation status)

Transportation dimension (length × width × height) (7260×3000×3000) mm

Machine weight 15000 Kg

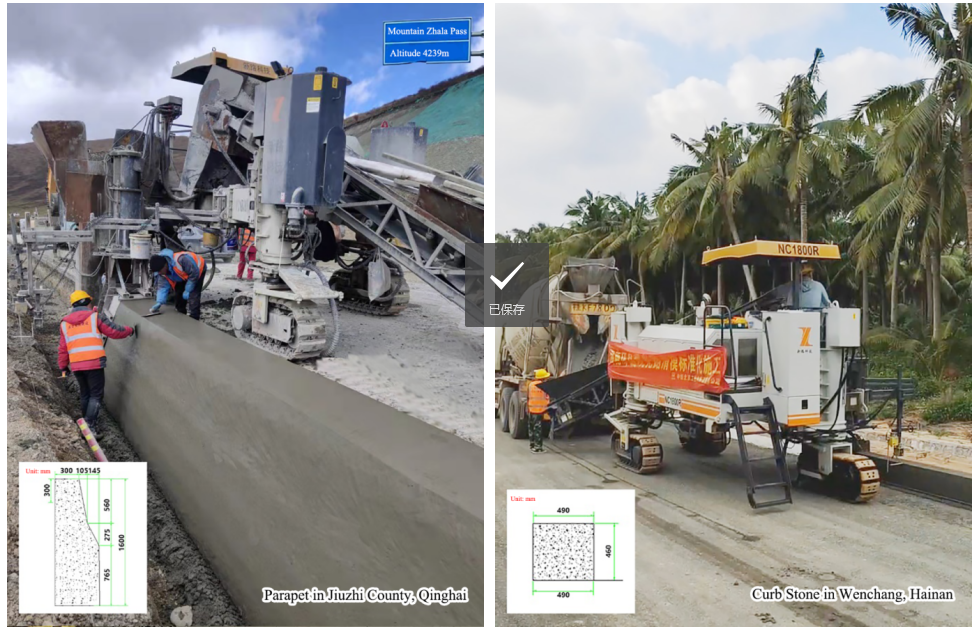

1. It is multi-purpose and can realize the accurate slipform paving of road drainage ditches, drainage channels, curbs, shoulder stones, concrete guardrail cement concrete structures, and farmland water conservancy channels by getting various molds changed and the vehicle status accurately adjusted and controlled.

2. It has three-track traveling, hydraulic independent drive, proportional control two-speed motor, planet-gear speed reducer with large rations, closed-loop control of paving speed, and PID adjustment to ensure the stability of paving speed and improve slipform paving quality; Its three-track steering device is equipped with displacement sensors and can walk like a crab and turn cooperatively, with a small turning radius to ensure that the vehicle is quickly in place.

3. Its engine has strong power; the hydraulic system is controlled by load-sensitive variables, and fuel is supplied according to the actual load size and speed, with low fuel consumption, energy conservation, and environmental protection.

4. Its humanized design of the console, man-machine interaction control panel, and clear graphic identification mark make the paver easy and free to be operated. The paver is equipped with an IoT platform, a construction management and monitoring system, and an alternative remote control device.

5. Hydraulic proportional control is adopted for the steering lifting, and the vehicle is equipped with two longitudinal slope sensors, one transverse slope sensor, and two steering sensors. The sensors and controller communicate with each other through the CAN bus to improve its response speed and stability, ensure accurate linear control and realize superimposed paving.

6. According to the needs of working conditions, right-side paving and middle paving can be realized; the inner and outer swing of the right front outrigger and the expansion of the left front outrigger and rear outrigger can be realized through hydraulic adjustment, with stronger adaptability; the hydraulic horizontal and vertical bidirectional adjustment is adopted for the mold fixing device and various molds can be quickly replaced.

7. The swing, tilt and expansion of the auger feeding device are hydraulically adjusted, which is convenient to be operated and suitable for various working conditions. The storage space is large, which can realize the secondary mixing of cement concrete.

IV. Construction Cases

The Company adheres to the principle of sustainable development, so we reserve the right to continuously improve the products without previous notice. The content is subject to continuous improvement without notice.

Contact: Mr Yin

Phone: +86-18606171122

whatsapp: +86-18606172828

Add: Xuzhou, Jiangsu, China